Exactly what are Precision Machining Solutions?

Precision machining services involve the removing of fabric from a workpiece to achieve exceptionally restricted tolerances and fantastic finishes. Utilizing advanced Computer system-controlled machines (CNC), these expert services can create factors with microscopic accuracy, often Utilized in industries like:

Aerospace

Professional medical units

Automotive

Electronics

Robotics

These parts ought to meet significant-tolerance machining specifications, often in microns, to function in basic safety-crucial or significant-efficiency environments.

Swiss Lathe Machining: The trick Powering Intricate Sections

Swiss lathe machining (also referred to as Swiss-form turning) is a specialized system ideal for manufacturing small, intricate, and superior-precision components. Prevalent in watchmaking and medical unit production, Swiss equipment use a sliding headstock that supports the fabric nearer into the cutting Instrument, lowering deflection and raising precision.

Benefits:

Very tight tolerances

Ideal for tiny diameter areas

Perfect for advanced aspect machining

Lessened cycle situations

Swiss lathes are important for producing factors where precision is non-negotiable, such as surgical instruments or aerospace fasteners.

Rapid Tooling Solutions: Speed Satisfies Scalability

Immediate tooling methods help brands to generate prototype molds or small-quantity injection molds speedily, minimizing direct occasions from months to just months. This solution is great for merchandise developers who require functional prototypes that intently mimic the ultimate merchandise.

Essential Positive aspects:

Quicker time to market

Cost-helpful for very low-volume manufacturing

Supports iterative design advancements

Perfect for bridge creation prior to full-scale producing

Quick tooling bridges the gap concerning prototyping and injection mildew creation, permitting for fast responses and layout optimization.

Reduced-Quantity Production: Flexibility Without the need of Compromise

Lower-volume production enables businesses to create higher-high-quality elements in portions ranging from fifty to a couple thousand. It’s ideal for startups, specialized niche merchandise, or market screening.

Why it Issues:

Decreases stock danger

Shortens products advancement cycles

Permits customization and versioning

Perfect for modest batch manufacturing

When combined with CNC precision pieces and fast injection molding, very low-quantity manufacturing makes certain cost-effectiveness and high-quality in early-stage solution lifecycles.

Vacuum Casting & Polyurethane Vacuum Casting

Vacuum casting is a flexible method utilized for developing high-fidelity prototypes and tiny generation operates utilizing silicone molds. It truly is Primarily helpful in plastic merchandise producing.

Polyurethane vacuum casting, especially, offers an array of content Houses—rigid, versatile, obvious, or coloured—rendering it perfect for:

Purchaser product enclosures

Automotive components

Functional testing versions

Simulated injection-molded areas

This method delivers a cost-effective alternate to comprehensive injection mould tooling, particularly for low-volume production.

CNC Precision Engineering: Where Innovation Meets Execution

CNC precision engineering combines advanced machining with design excellence to produce intricate parts for demanding industries. By leveraging multi-axis CNC machining, manufacturers can achieve complex geometries with much less setups, cutting down Charge and increasing accuracy.

Well-known Applications:

Aerospace brackets and structural factors

Professional medical implants and devices

Robotics and automation elements

Automotive engine components

The guts of CNC precision engineering lies in its flexibility—no matter whether it’s CNC milling and turning, 5-axis machining, or custom programming for elaborate aspect machining, it delivers reliable and repeatable success.

Substantial-Precision Machining for Demanding Industries

When tolerances are razor-skinny, high-precision machining results in being essential. Aerospace and healthcare purposes typically demand Proportions to get held inside ±0.002 mm.

Superior-precision environments incorporate:

CNC machining for aerospace: Lightweight, significant-strength alloys which include titanium and Inconel are machined with actual tolerances for turbines, brackets, and structural pieces.

CNC machining for health care devices: Stainless-steel and biocompatible plastics are used to manufacture orthopedic implants, dental equipment, and surgical devices.

These elements will have to not merely fulfill stringent dimensional prerequisites but additionally adhere to basic safety and material expectations.

CNC Milling and Turning: The Spine of Modern Machining

Most recent equipment retailers present both CNC milling and turning companies to address a wide range of areas. Milling is perfect for creating flat surfaces, slots, and holes, although turning excels at cylindrical parts.

When combined into multi-axis CNC machining methods, these abilities make it possible for for complete elements to get built in a single setup—bettering effectiveness and lessening human mistake.

Typical components contain:

Gears

Housings

Connectors

Flanges

Brackets

Swift Injection Molding: Rapid, Purposeful, and Scalable

Rapid injection molding utilizes aluminum or delicate steel molds to create plastic areas in times in lieu of months or months. It’s perfect for:

Useful screening

Pre-generation validation

Pilot operates

Early buyer samples

With injection mildew tooling, makers can obtain in close proximity to-closing portion Homes, making it possible for teams to test and validate styles before investing in tricky tooling for mass output.

Significant-Tolerance Machining: Assembly one of the most Stringent Specs

Substantial-tolerance elements are frequently mission-crucial, demanding restricted dimensional Handle. Regardless of whether you’re creating a turbine blade or a catheter part, large-tolerance machining ensures the products performs as meant.

Crucial considerations:

State-of-the-art inspection equipment (CMM, laser scanning)

Temperature-controlled environments

Precision fixturing and Resource paths

Knowledgeable machinists and engineers

CNC Machining for Healthcare Products: Security and Precision Put together

The health care sector demands the utmost precision and regularity. CNC machining for healthcare equipment requires demanding documentation, cleanliness expectations, and materials that adjust to FDA or ISO regulations.

Widespread medical areas include:

Bone screws and plates

Surgical clamps

Dental abutments

Endoscopic elements

A chance to machine smaller, delicate elements with great accuracy helps make Swiss lathe machining and multi-axis CNC critical in healthcare production.

Injection Mould Tooling and Manufacturing: From Principle to Sector

Injection mold tooling is the entire process of developing hardened metal molds for mass manufacturing. It truly is an important expense, but when you are All set for scale, it’s quite possibly the most Price-successful system for plastic products manufacturing.

As soon as tooling is full, injection mildew generation can churn out hundreds or many consistent components at a reduced per-device Expense.

Contemporary mould design frequently consists of:

Conformal cooling channels

Slide and lifter mechanisms

Multi-cavity and loved ones mildew techniques

Automated element ejection

Conclusion: Embrace the Future of Precision Manufacturing

The planet of Sophisticated manufacturing is quickly evolving. With access to chopping-edge methods like Swiss lathe machining, vacuum casting, multi-axis CNC machining, and immediate injection molding, providers can acquire, take a look at, and scale merchandise with unprecedented speed and precision.

Whether or not you're prototyping a completely new product or service or ramping up for prime-volume production, products and services like CNC precision engineering, significant-precision machining, and injection mildew tooling offer the applications required to remain ahead in aggressive industries like aerospace, health-related, and customer electronics.

Precision machining services are no more a luxury—they’re a requirement for any person serious about product or service innovation and production excellence.

Keywords Recap for SEO:

Precision machining expert services

Swiss lathe machining

Speedy tooling solutions

Lower-volume production

CNC precision parts

Vacuum casting

Polyurethane vacuum casting

CNC precision engineering

Significant-precision machining

CNC machining for aerospace

Little batch producing

Sophisticated section machining

Injection mold tooling

Plastic product or service manufacturing

Multi-axis CNC Injection mold tooling machining

CNC milling and turning

Swift injection molding

Higher-tolerance machining

CNC machining for clinical gadgets

Injection mildew production

Emilio Estevez Then & Now!

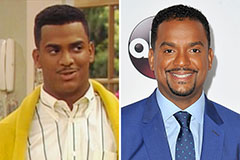

Emilio Estevez Then & Now! Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Barry Watson Then & Now!

Barry Watson Then & Now! Rachael Leigh Cook Then & Now!

Rachael Leigh Cook Then & Now! Mary Beth McDonough Then & Now!

Mary Beth McDonough Then & Now!